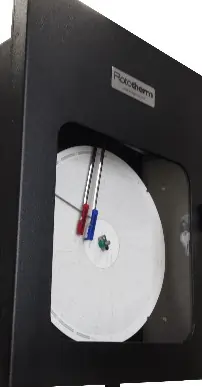

Rototherm chart recoders repair and calibration services

Chart recorder Calibration and Maintenance

• The recording pen comes with screws for friction and zero adjustment, which are factory set to optimal settings.

• Minor adjustments may be required for correct operation due to plant conditions and usage.

• Mechanical calibration is crucial for accurate setting of zero, span, and linearity of the recording pen.

• Adjustments must be performed in the order listed and the instrument must settle before readings and adjustments are made.

• For temperature pen calibration, follow steps:

• Allow the recorder to stabilize with the measuring element in a low temperature just above scale minimum.

• Adjust the pen fine zero adjustment screw to bring the pen to the correct reading.

• If the pen reading is significantly out, adjust the pen fine zero screw to bring the pen arm in-line with the pen arm bracket and loosen the coarse zero adjustment screw holding the compensator arm to the temperature bourdon tube centre.

• For pressure pen calibration for pressure ranges 2.5 bar to 40 bar, follow steps:

• Connect a suitable pressure regulator and calibrated test gauge to the instrument pressure line.

• Ensure all linkages are free to pivot and pens align and pass each other.

• Fit a dummy chart plate and correct chart.

• Set pen to read zero on chart.

• Make small zero adjustments using pressure take-off assembly on bourdon.

• Overload the bourdon tube by 15% of the maximum pressure range before starting to calibrate and check for any leaks.

• Check the recorder accuracy is within ±1% full-scale deflection at this mid-point.