Automobile calibration UAE

Car lift inspections are crucial for ensuring the safety and reliability of the equipment used in auto workshops. Here are some key points about the process:

Inspection Components

Structural Integrity: Checking for any signs of wear, corrosion, or damage to the lift’s structure.

Mechanical Components: Inspecting the moving parts such as chains, pulleys, and cables for wear and proper lubrication.

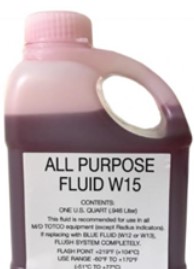

Hydraulic Systems: Ensuring there are no leaks and that the hydraulic fluid is at the correct level.

Electrical Systems: Verifying that all electrical components, including switches and wiring, are functioning correctly.

Safety Features: Testing safety locks, emergency stop buttons, and other safety mechanisms to ensure they are operational12.

Frequency of Inspections

Routine Inspections: Typically conducted daily or weekly by workshop staff to identify any immediate issues.

Thorough Examinations: Conducted by a competent person at least once a year, as required by regulations such as the Lifting Operations and Lifting Equipment Regulations (LOLER)13.

Benefits

Safety: Reduces the risk of accidents and injuries.

Compliance: Ensures adherence to health and safety regulations.

Efficiency: Helps maintain equipment performance and avoid costly downtime.

Certification

After a thorough examination, a certificate is usually issued, confirming that the lift meets safety standards and is safe to use2.