Programmable Logic Controllers

• PLCs are digital electronic devices that use a programmable memory to store instructions and implement specific functions.

• PLCs have evolved from electromechanical devices used to control manufacturing operations, industrial processes, and heavy equipment.

• The transition to solid-state devices and digital electronics in the late 1960s led to the development of programmable controllers (PLCs).

• PLCs have capabilities far exceeding those of older electromechanical controllers, allowing for flexible circuit construction techniques, reduced downtime during changeovers, improved efficiency, and can be housed in a small space.

• The first programmable controllers could only perform a limited number of functions, such as two-state control, AND, OR, and some limited timing functions.

• Today, PLCs can perform all logic functions, do arithmetic operations, and sense analogue changes in manufacturing operations.

• The unique features of a modern PC are flexibility, operational efficiency, and versatility.

• The I/O capacity of a PLC is also discussed, along with the importance of memory allocation and programming devices.

• A PLC can be monitored through indicating lights or external devices that display program execution status.

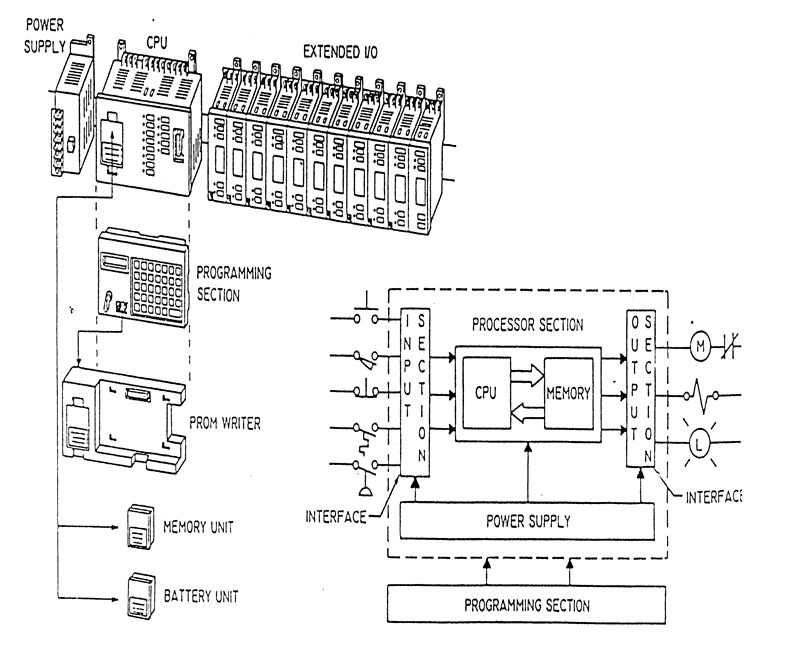

• The four basic parts of a programmable controller are the power supply, input/output interface sections, processor section, and programming section.

• The power supply provides all necessary voltage levels required for the programmable controller's internal operations, while the input/output interface section functions as the eyes, ears, and hands of the programmable controller.