Emergency Shut Down Systems (ESD)

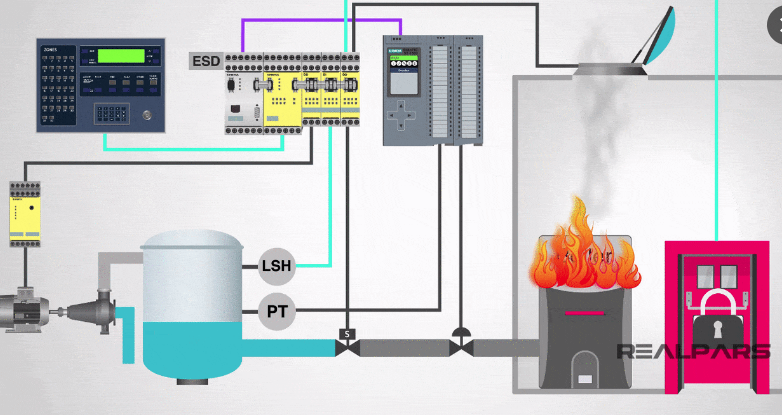

• ESD system is crucial for protecting personnel, environment, and plant from harm.• It ensures planned automatic shutdown and isolation of processes and utilities in hazardous situations.

• The system should act in cases such as sudden loss of feed, process upsets, confirmed detection of fire or gas, and a serious fault in equipment.

• Pre-alarms provided in the DCS provide early warning of potential process upsets, equipment faults, and detection of fire or gas.

• Inhibits and overrides must be active, with all inhibits removed, and outputs armed.

• The ESD system comprises two identical PLCs, each operating a separate path, monitoring field inputs for change of state and generating automatic control outputs.

• The ESD system can be initiated manually, either locally at the equipment or remotely from local control/equipment rooms.

• Units and systems can be shut down by upset conditions within the unit or system, but they do not directly initiate general shutdowns or other units.

• Manual initiation of ESD-1 will shut down all production facilities, selectively isolating platform areas.

• ESD-2 shutdown with automatic depressurization on USSC will shut down and isolate the platform as per ESD-1, depressurizing each isolated section to flare.

• Manual switch in both the LCR and CCR may be used to initiate opening of blowdown valves to depressurize the 36 inch MOL and sphere launcher.

• Standing Instruction No. 15/04/96 advises against re-opening an emergency shutdown valve against a full or significant pressure difference/drop to avoid damage and reduce its integrity in the future.