Scales & Balances Repair and Calibration Services UAE

• Employs Class F1 calibration weights as per OMIL to ensure device accuracy and reliability.

• Offers on-site or laboratory calibration for most balance and force device models.

• Calibrations ensure accuracy and prevent loss of sales or impact on product quality.

• Can calibrate scales for pallet trucks weighing up to 1.5 tonnes.

• Provides on-site calibrations using an ISO9001 calibration lab.

• Repairs test equipment if necessary, ensuring safe use and accurate readings for an additional year.

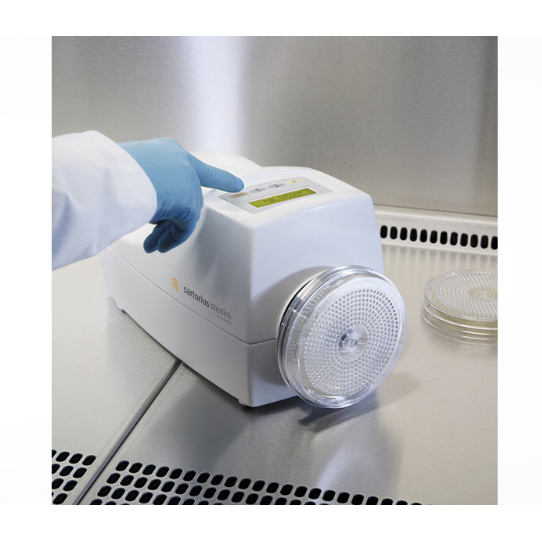

• Offers calibration on various scales and balances, including precision balances, lab balances, analytical balances, and more.

• Calibration is necessary for various industries including building, food, pharmaceutical, and medical sectors.

• Weighing scale calibration is necessary for health, safety, invoicing, and other reasons.

• Weighing scales can lose accuracy due to wear and tear on mechanical or electronic components and environmental influences.

Understanding Automatic and Non-Automatic Scales

Automatic Scales

• Can carry out successive cycles of weighing without operator assistance.

• Classified under Measuring Instruments Directive regulations.

• Need an operator to confirm the weight reading.

• Any operator action influencing the outcome is included in determining the weighing result.

• Verification of the weighing result is a decision about accepting each weighing result based on the indication.

Weighing Scales

• SI measurement unit of weight is the kilogram (kg).

• Common units used by scales include kilogram, milligram (mg), gram (g), and tone (t).

• Scales may be equipped with load-measuring device, display, printer, and preset tare function.

Classification of Weighing Scales

• Classified according to verification scale interval (e), number of verification scale intervals (n), and minimum capacity (Min).

• Non-automatic weighing instruments are characterized by their accuracy class defined in OIML R76-1.

About Scale Calibration

• Calibration consists of measurements performed, calculation of measuring results, determination of measurement uncertainty, and issuance of a calibration certificate.

• The object of calibration is the indication provided by the instrument when a load is applied.

• Calibration involves placing test loads on the scale under specified conditions, determining the indication's error or variation, and assessing the measurement uncertainty associated with the results.

• Calibration range typically covers the entire weighing range.